How Can You Earn Money Quickly From Solder Repair?

Are you the tinkering type? Love to mend broken electronics or fix internal wiring? Yes! In that case, you might love soldering too. If soldering is your hobby, or you count it as an extra skill you possess, you will be pleased to know that you can make money with solder repair too.

Make Money From Solder Repair: A Beginner’s Guide To Soldering Skills And Business Opportunities

Contents

Indeed, there are actually people out there ready to pay for solder repair. If I piqued your interest, follow my guide to discover how to make money with solder repair.

What Is Soldering?

Since the dawn of modern-day electronics, soldering has been its essential part. Being an indispensable part of electronics, soldering also provides countless earliest opportunities to those adept at it. But before that, let’s understand what soldering actually is.

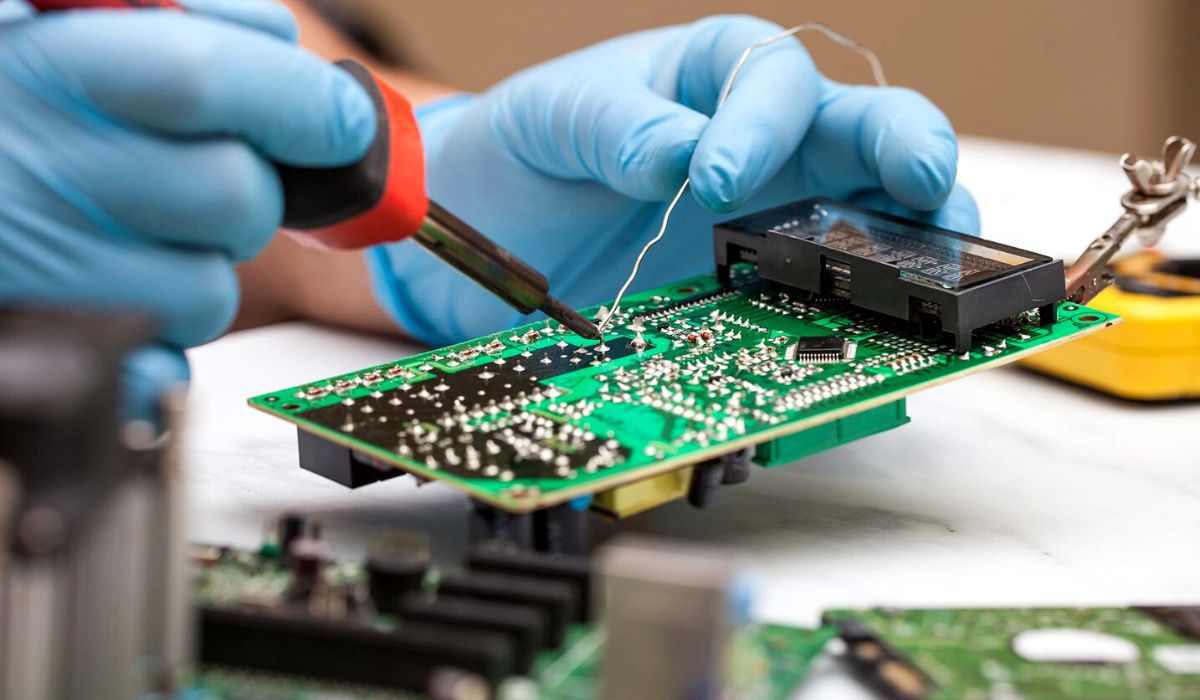

In simple terms, soldering is the process of joining two metal surfaces with the help of a solder. In the soldering process, solder, a metal alloy, is heated to a high temperature (600 degrees Fahrenheit) till it melts and covers the two surfaces that are meant to be connected.

When this melted solder is cooled, it solidifies, creating strong bonds that hold the two metal surfaces together. The solder is often heated with the help of an iron rod connected to a temperature controller.

Types Of Soldering

The soldering process is meant to join two metal surfaces together and create a strong bond, so they don’t detach from each other. However, you might be amazed to know that there are indeed many types of soldering.

Let’s discuss them in detail:

1. Soft Soldering

Soft soldering, as the name suggests, is a type of soldering that uses a low-melting-point filler metal to join two or more metal items together. It means the solder involved in this soldering process melts at comparatively lower temperatures, usually below 350 degrees Fahrenheit.

And because soft soldering can be performed at relatively low temperatures, it is particularly suitable for joining delicate or heat-sensitive materials. However, it doesn’t make strong bonds because the solder or the filler metal has a low melting point.

Soft soldering is often used in the electronics industry to join together the components of a circuit board. Besides, it is also extensively used in jewelry making and other fields. The most commonly used filler metals for soft soldering are tin-lead alloys; however, you will find solder consisting of tin-copper and tin-silver alloys too.

2. Hard Soldering

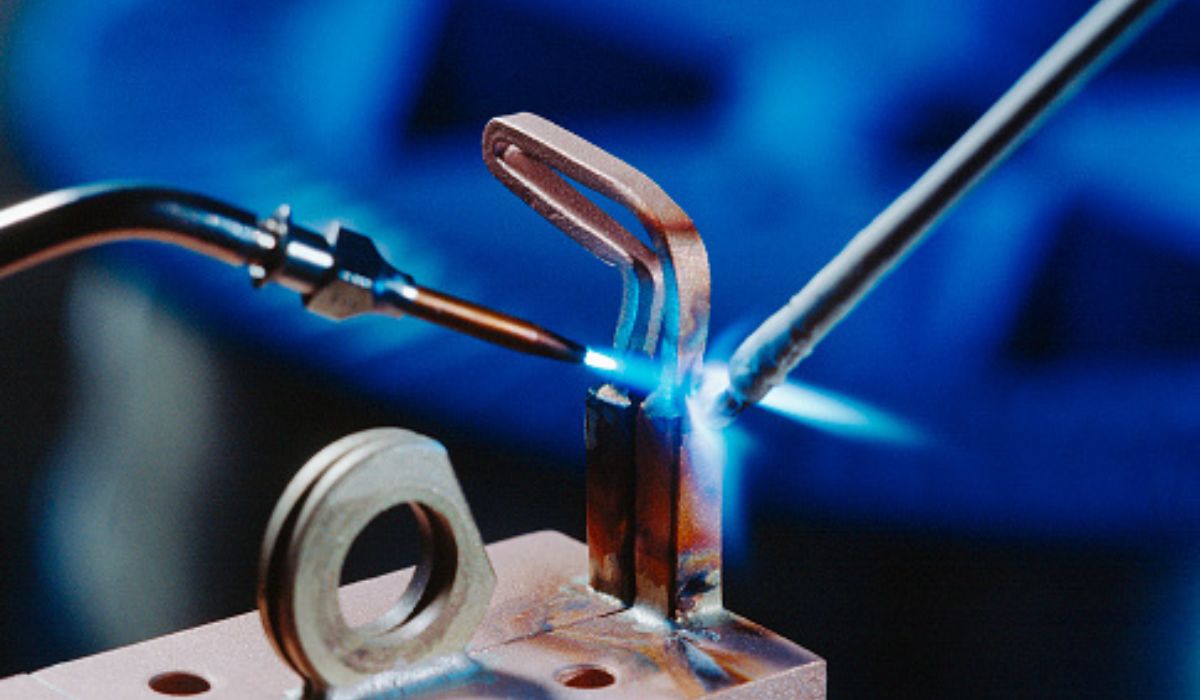

The name is kind of a giveaway of the type of soldering here. Hard soldering uses high-melting-point filler metal to join two metal items together. Unlike soft soldering, which uses a low-melting-point filler metal, hard soldering requires higher temperatures to melt the filler metal or the solder.

The temperature needed to melt hard soldering metal filler is around 450 °C or above. Because of this property, the soldering joints are quite sturdy; therefore, hard soldering is employed where the bond needed to hold the joining metals should be strong.

Hard soldering is used in automotive repair and metalworking. Silver and gold are the most commonly used filler metals for hard soldering, although other alloys, such as copper-zinc and nickel-silver, are also sometimes used.

3. Brazing

Like hard soldering, brazing also uses filler metal with a high melting point, often above 450 degrees centigrade.

Although the filler itself is not heated, instead, the adjoining metal surfaces are generally heated above the melting temperature of the filler metal, and the solder is introduced before the heating or between the process. Brazing is used in electronics, Transportation, construction, etc.

How To Make Money From Soldering?

Now that you are clear about the basics of soldering, let’s now focus on learning how you can utilize your skills and make money with solder repair;

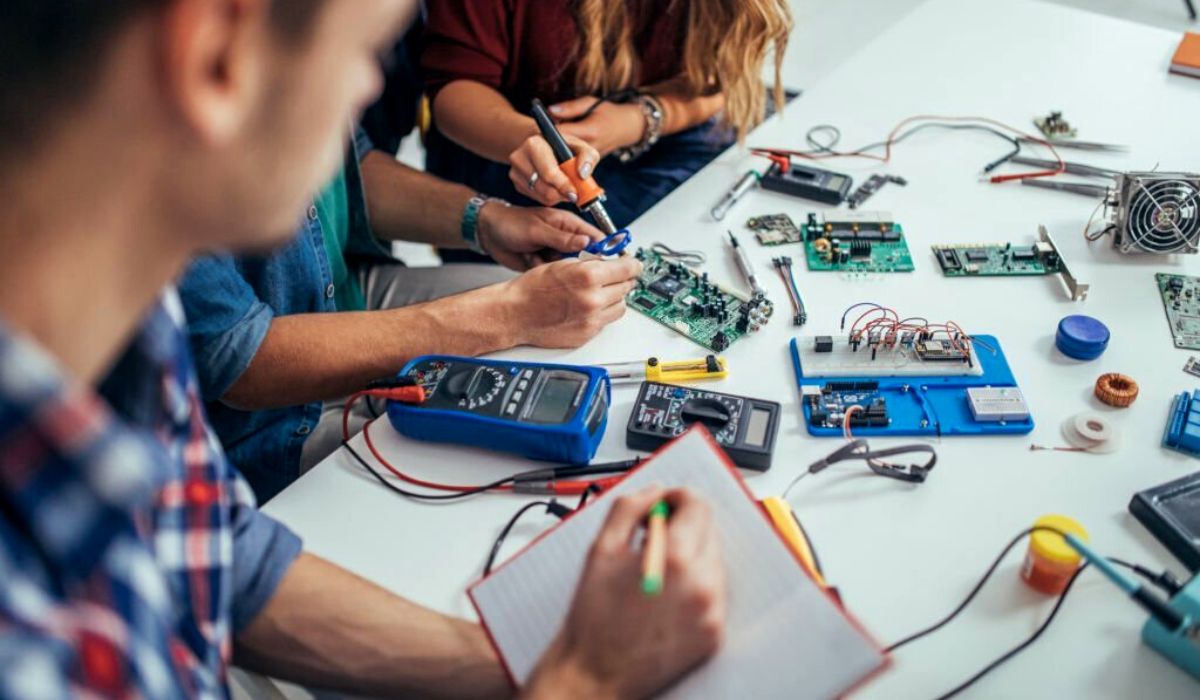

Learning

The first step to making money with solder repair is to gain proficiency in the trade. Understand that it’s a specialized skill and therefore needs expertise. Unless you are not proficient in soldering, your chances of making good earnings with solder repair are slim.

You can quickly learn soft soldering within the comfort of your home; however, it’s better to reach out to an expert and learn all the trade secrets for hot soldering and brazing.

Practicing

You must have heard that practice makes the man perfect. I have already told you proficiency is a must in this trade.

For mastery, you must practice. The best way is to do an apprenticeship under an expert. You can also apply for an entry-level position with vendors that offer solder repair services.

Let People Know your Talent

Once you have gained proficiency, it’s time to let people know about your skills. A little bit of marketing will bring you clients that will propel your career as a solder repair service provider in the right direction.

Social media is the most powerful tool you have at your disposal to let people know about your talent. You can employ paid ads for targeted marketing or your services. Additionally, you can also set up Google my business page to make your service known to locals of your area.

Cold Call Businesses

Another powerful tool you can employ to make your service known to people and bring more clients is cold calling. It might sound dated, but cold calling can bring you tons of business.

You can even employ a virtual assistant to do the work for you if you aren’t comfortable with cold calling. Understand that the more people you can reach, the more clients you can make and, by extension, the more money you can make.

Selling assembled boards on eBay

There’s a market out there for assembled boards. You can easily make decent money selling assembled boards on eBay. All you need is to list your products on eBay. Once you receive an offer, you can complete the board and send it to the customer.

Other ways

You can also make educational videos on YouTube regarding solder repair to make money. Additionally, hobby videos also attract tons of viewers on YouTube. You can record your soldering process, configuring board, or other solder work and upload it on YouTube.

How Much Money Can You Make Soldering?

Well, it is difficult to pinpoint precisely how much you can make from solder repair, as it will depend on a variety of factors, such as your skill level, the demand for your services, and the rate you can charge for your services. However, per the payscale website, you can earn an average of $21.72 / hour or around $33,503 a year with solder repair.

You can either set up your own business or join a company. If you choose your own setup, you have to factor in the setup cost. But you will be free to determine your own rates.

On the other hand, if you work for a company that offers solder repair services, you will likely earn a regular salary, but you will have less control over your income. In general, the amount of money you can make from solder repair will depend on the value of your services and how you market them.

How Much Money Do We Need For A Soldering Work Set Up?

To start a solder repair business, you must factor in several aspects. The costs for solder repair setup can vary depending on the location of the business, the size of the operation, and the specific equipment and tools you’ll need to purchase.

In general, however, you need at least five to ten thousand dollars to get started, and potentially more if you plan to rent a commercial space and hire employees.

Is Soldering Harder Than Welding?

Soldering is generally considered easier than welding because it requires lower temperatures and less skill to perform.

Welding, on the other hand, involves heating the metal items to a high temperature and using pressure to join them together. This requires more skill and training to perform correctly and is also more physically demanding.

Additionally, welding is typically used to join together thicker and stronger metals, such as steel.

In contrast, soldering is more commonly used for thin and delicate materials, such as those used in the electronics industry.

What Are Different Soldering Jobs?

Many different jobs involve soldering. However, specific tasks and responsibilities of each job will vary depending on the industry and the employer.

Some typical soldering jobs include:

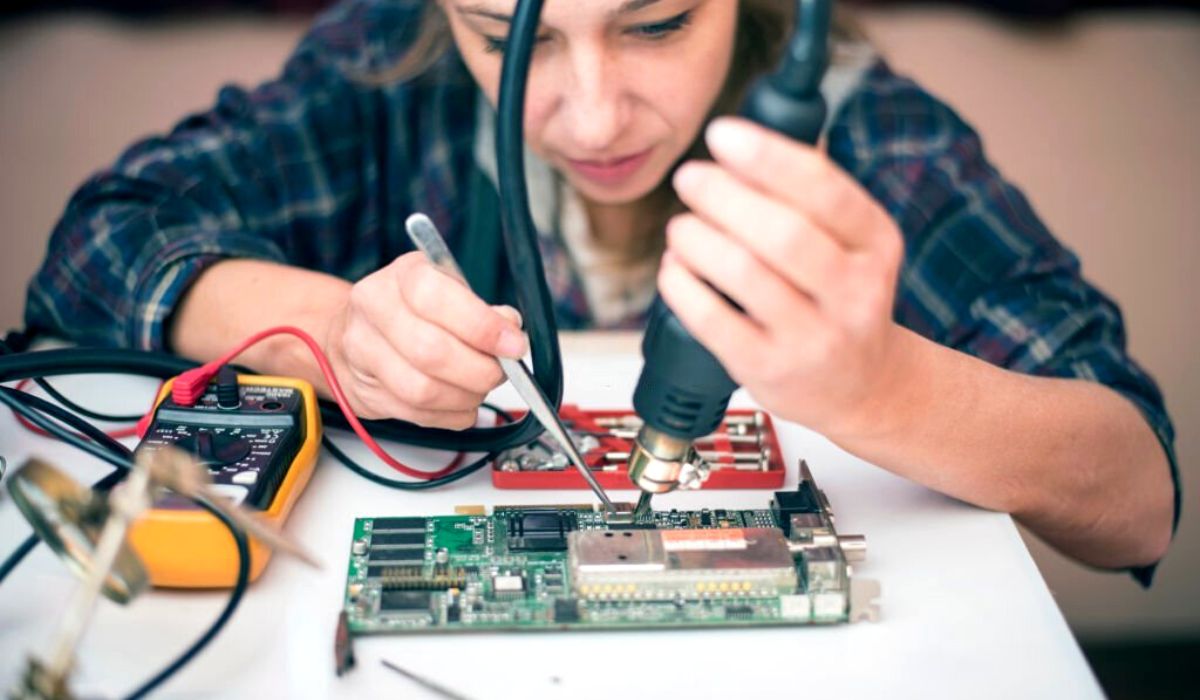

- Electronics technician: Electronics technicians use soldering to assemble and repair electronic devices, such as circuit boards, computers, and appliances.

- Plumber: Plumbers use soldering to join together pipes and fittings in plumbing systems.

- Jewelry: As a jewelry designer, you will use soldering to create and repair jewelry. Besides, soldering can also be used to join metals, gemstones, and other materials to create custom pieces.

- Automotive technician: Automotive technicians use soldering to repair and maintain the electrical systems of cars and other vehicles.

- Metalworker: Metalworkers use soldering to join together pieces of metal to create a wide range of products, from structural components to decorative items.